Introduction

Heating, ventilation, and air conditioning (HVAC) systems are essential components in buildings, providing comfort and maintaining indoor air quality. These systems rely on a steady and reliable power supply to function efficiently. The power cable used to deliver electricity to HVAC units plays a crucial role in ensuring optimal performance and safety. In this article, we will explore the importance of power cables for HVAC systems, the types of cables commonly used, best practices for installation and maintenance, and tips for selecting the right power cable for your HVAC setup.

Importance of Power Cables for HVAC Systems

Power cables are the lifeline of any electrical system, including HVAC systems. The quality and reliability of the power cable directly impact the performance, efficiency, and safety of the HVAC equipment. Here are some key reasons why power cables are essential for HVAC systems:

1. Reliable Power Supply: HVAC systems require a consistent and uninterrupted power supply to operate efficiently. Power cables deliver electricity from the main electrical panel to the HVAC units, ensuring that they have the necessary power to function properly.

2. Safety: High-quality power cables are designed to handle the electrical load of HVAC systems without overheating or causing electrical faults. Using the right power cable reduces the risk of electrical hazards such as short circuits, fires, and electrical shocks.

3. Efficiency: Properly sized and installed power cables minimize voltage drops and energy losses, allowing HVAC systems to operate at their optimal performance levels. This not only ensures comfort for building occupants but also helps reduce energy consumption and operating costs.

4. Longevity of Equipment: By providing a stable power supply, quality power cables help extend the lifespan of HVAC equipment. Unstable or fluctuating power can damage sensitive components in HVAC units, leading to premature failure and costly repairs.

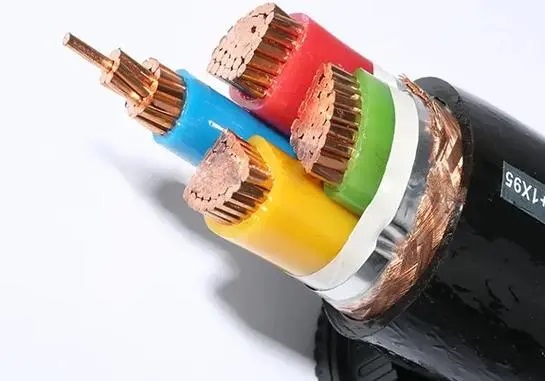

Types of Power Cables for HVAC Systems

Several types of power cables are commonly used in HVAC systems, each with its own characteristics and applications. The choice of power cable depends on factors such as the electrical load, environmental conditions, and installation requirements. Here are some of the most common types of power cables used in HVAC systems:

1. Non-Metallic Sheathed Cable (NM Cable): NM cable, also known as Romex cable, is a common type of power cable used in residential HVAC installations. It consists of two or more insulated conductors wrapped in a flexible plastic sheath. NM cable is suitable for indoor applications where moisture and physical damage are not significant concerns.

2. Armored Cable (AC): Armored cable, also known as BX cable, is a type of power cable with a metal armor layer surrounding the insulated conductors. AC is commonly used in commercial and industrial HVAC installations where mechanical protection is required. The metal armor provides enhanced durability and resistance to physical damage.

3. Flexible Metal Conduit (FMC): FMC is a flexible metal conduit that houses insulated electrical wires and provides mechanical protection in HVAC installations. FMC is commonly used in applications where flexibility is required, such as connecting HVAC units to power sources in tight spaces.

4. Metal-Clad Cable (MC Cable): MC cable is similar to AC but has an additional aluminum or steel interlocking armor layer for enhanced protection. MC cable is commonly used in outdoor HVAC installations or areas where moisture, corrosion, or physical damage are concerns.

5. Type THHN/THWN Wire: THHN (Thermoplastic High Heat-resistant Nylon-coated) and THWN (Thermoplastic Heat and Water-resistant Nylon-coated) wires are commonly used as individual conductors in HVAC power cables. These wires have thermoplastic insulation that provides resistance to heat, water, and abrasion, making them suitable for a wide range of HVAC applications.

Best Practices for Installation and Maintenance of Power Cables

Proper installation and maintenance of power cables are essential for ensuring the safe and reliable operation of HVAC systems. Here are some best practices to follow when installing and maintaining power cables for HVAC systems:

1. Size and Type Selection: Select the appropriate size and type of power cable based on the electrical load, voltage rating, and environmental conditions of the HVAC installation. Control cable with a qualified electrician or HVAC technician to determine the correct cable specifications for your system.

2. Routing and Support: Route power cables away from sharp edges, moving parts, and heat sources to prevent physical damage. Use cable supports, clamps, and conduits to secure and protect the cables from mechanical stress and environmental hazards.

3. Proper Termination: Ensure that power cables are terminated correctly at both ends to prevent loose connections or exposed conductors. Use proper connectors, terminals, and junction boxes to terminate the cables in accordance with local electrical codes and manufacturer guidelines.

4. Overcurrent Protection: Install overcurrent protection devices such as circuit breakers or fuses to prevent excessive current flow through the power cables. The overcurrent protection should be sized according to the ampacity rating of the cables to prevent overheating and electrical faults.

5. Regular Inspection and Testing: Periodically inspect power cables for signs of wear, damage, or overheating. Perform electrical tests such as continuity checks, insulation resistance tests, and voltage measurements to ensure the integrity of the cables and connections.

6. Moisture Protection: In outdoor or wet locations, use moisture-resistant power cables and seal electrical connections with waterproof materials to prevent water ingress. Protect power cables from exposure to moisture, chemicals, and corrosive environments to maintain their performance and longevity.

7. Grounding and Bonding: Ensure that power cables are properly grounded and bonded to prevent electrical shocks and protect against lightning strikes. Follow local electrical codes and manufacturer guidelines for grounding practices in HVAC installations.

Selecting the Right Power Cable for Your HVAC System

When selecting a power cable for your HVAC system, consider the following factors to ensure optimal performance and safety:

1. Electrical Load: Determine the electrical load requirements of your HVAC system, including voltage, current, and power ratings. Choose a power cable with the appropriate ampacity and voltage rating to handle the electrical load without overheating or voltage drops.

2. Environmental Conditions: Consider the environmental conditions where the power cable will be installed, such as temperature extremes, moisture, chemicals, and physical hazards. Select a power cable with insulation and jacket materials that are suitable for the specific environmental factors present in your HVAC installation.

3. Installation Requirements: Evaluate the installation requirements of your HVAC system, including cable routing, bending radius, support spacing, and termination methods. Choose a power cable that meets the installation guidelines and specifications provided by the manufacturer and relevant codes.

4. Compliance and Certification: Ensure that the power cable meets industry standards and regulatory requirements for electrical safety and performance. Look for cables that are UL (Underwriters Laboratories) listed, CSA (Canadian Standards Association) certified, or comply with other national and international standards for electrical products.

5. Longevity and Durability: Select a power cable that is durable, reliable, and designed for long-term use in HVAC applications. Consider factors such as insulation thickness, conductor material, and jacket material to ensure that the cable can withstand the rigors of daily operation and environmental exposure.

Conclusion

Power cables are critical components of HVAC systems, providing the necessary electrical supply for heating, ventilation, and air conditioning equipment to function effectively. By selecting the right type of power cable, following best practices for installation and maintenance, and ensuring compliance with safety standards, you can optimize the performance, efficiency, and safety of your HVAC system. Whether you are installing a new HVAC system or upgrading an existing one, investing in high-quality power cables is essential for achieving reliable operation and long-term durability. By understanding the importance of power cables and following the guidelines outlined in this article, you can ensure that your HVAC system remains in top condition and provides comfort for building occupants for years to come.